Functional Safety & Cyber Security Certification

BYHON, independent division of H-ON a TÜV Rheinland Company, is an ANSI Accredited Product Certification Body in compliance with IEC 17065 and Chartered Lab for IEC 17025, that provides Functional Safety certification according to IEC 61508 and Cyber Security certification according to IEC 62443 standard and ISASecure® scheme.

Why is certification according to international standards important?

Why is certification according to international standards important?

With the increasing development of international trade and the growing demands to determine whether a product complies with standards, it is becoming increasingly important to demonstrate compliance with either functional safety or cyber security (or both) requirements.

Certification helps companies to reach new customers and open up new markets. In terms of either functional safety or cyber security, a certification allows a company to demonstrate through a third party that a product complies with international safety, security and quality standards.

Accreditation for SIL Certification

Functional Safety

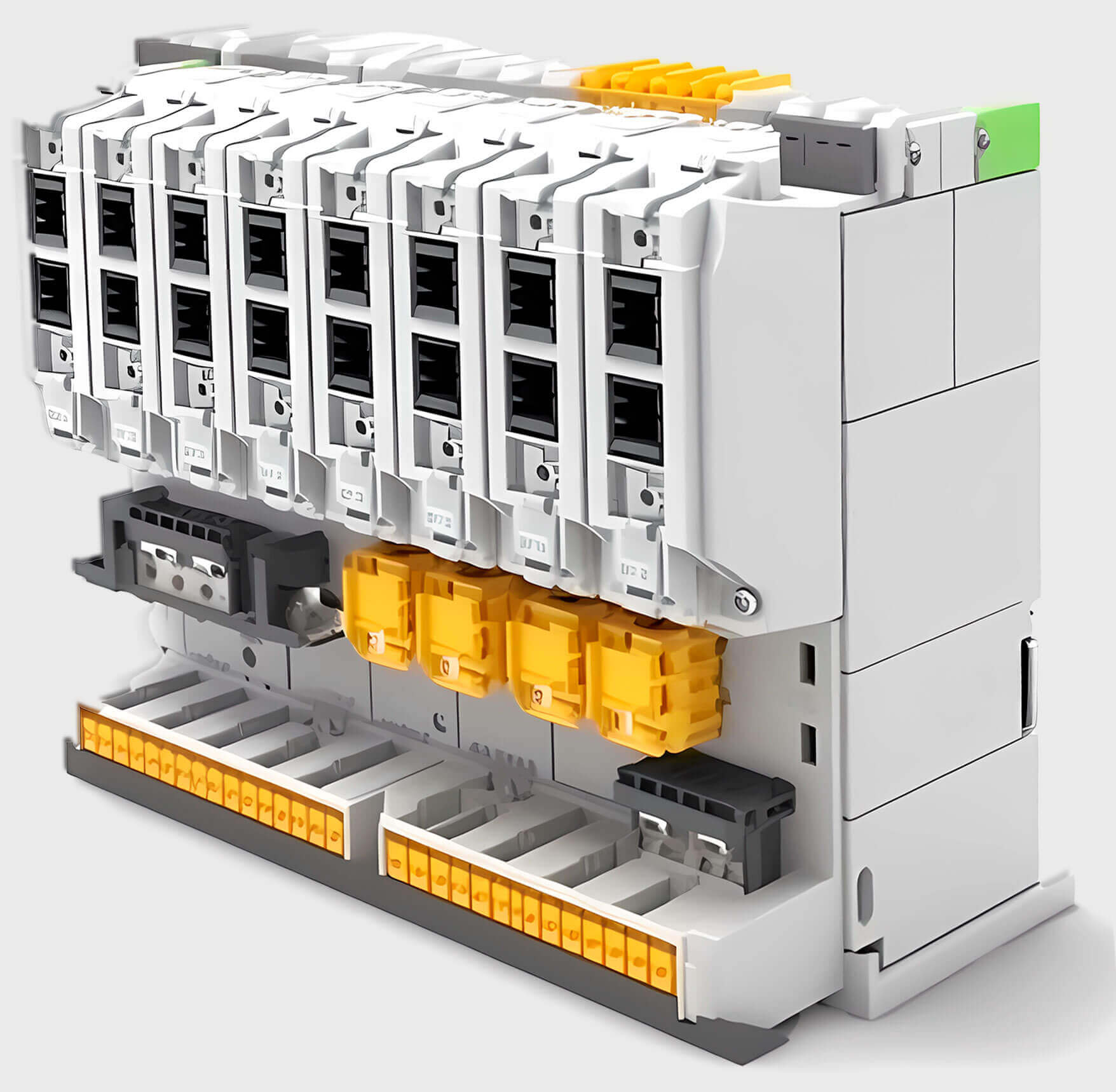

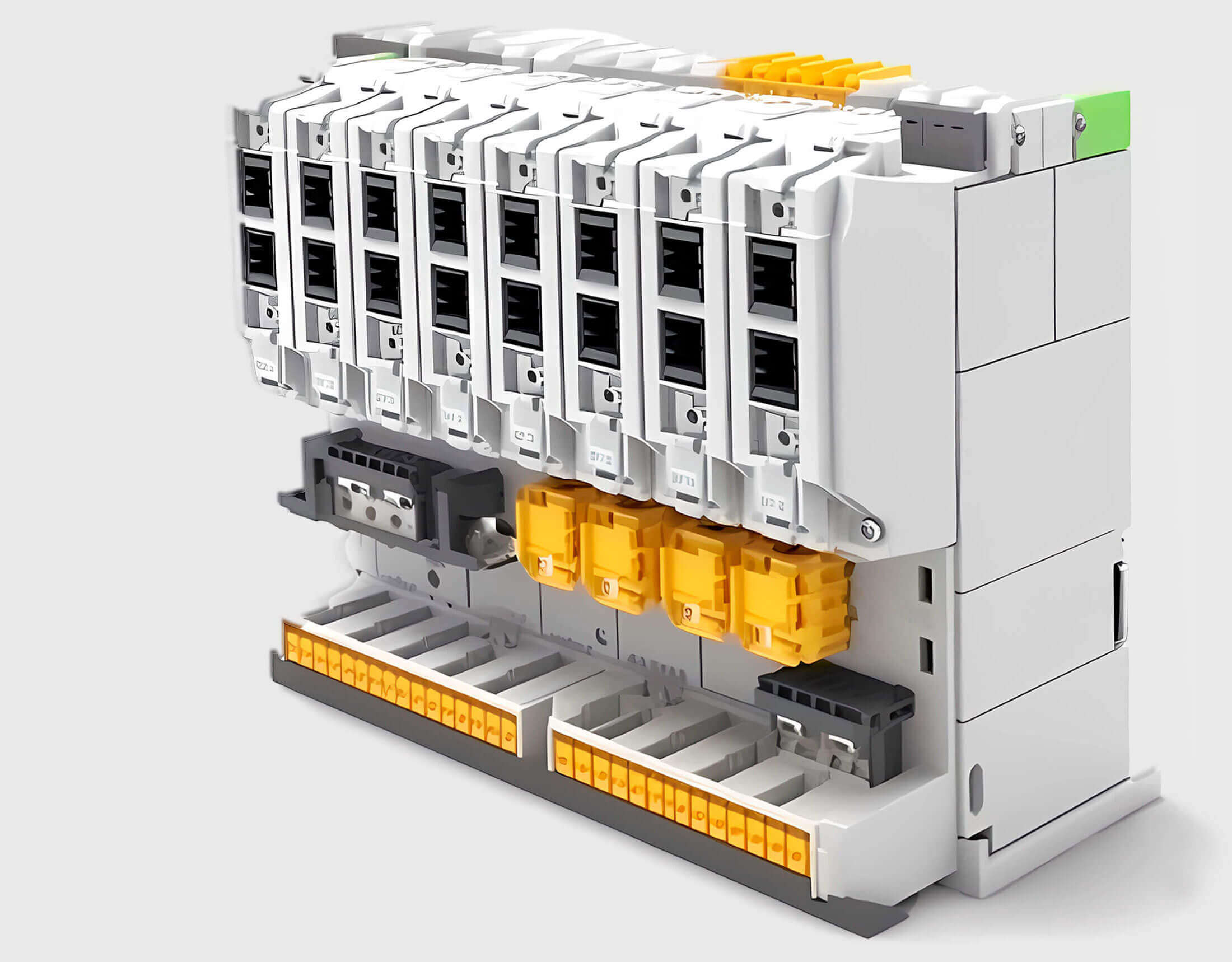

Functional Safety is the part of the overall safety of a product or system that depends on the proper functioning of electrical, electronic and programmable electronic equipment (E/E/PE) used in safety systems, both in normal operation and in faulty conditions.

Continue ReadingFunctional

Safety

Industrial Cyber Security

Industrial Cyber Security is the part of the overall security of an Industrial Automation and Control System (IACS) that depends on the proper security development lifecycle used by product suppliers, where products include DCS and SCADA systems, and components such as embedded devices and software applications.

Continue ReadingIndustrial Cyber Security

SIL Certification

BYHON provides certification services for Functional Safety Management Systems, Products and Systems, in compliance with international safety and quality standards.

Find moreBYHON Academy

BYHON provides comprehensive functional safety and cyber security training programs focused on various technical topics.

Find moreIEC 62443 Certification

BYHON performs Industrial Cyber Security certification and assessment in compliance with international security standard IEC 62443.

Find more